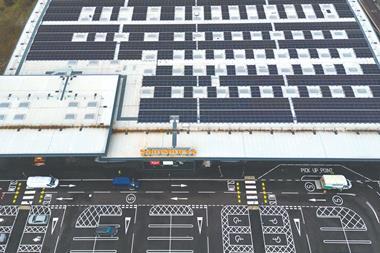

Now our sights are turned to economic recovery, there is one big opportunity for our sector: reshoring. It means returning production, supply chains and operations to the UK.

Touted as a solution to environmental sustainability, reshoring cuts out polluting shipping, road and air freight, and brings the added benefit of jobs.

Mismatched worldwide lockdowns might have played havoc with supply chains, but they have also created an opportunity here in our home region of the North East to tout for business. With a healthy supply of skilled labour, good connectivity and proximity to markets, we are in a prime position to accommodate businesses establishing or reorienting operations.

To capitalise on this, we need a strategy to target specific sectors. The North East already has strengths in automotive manufacturing, food production and industrial coatings. We have the know-how and supporting ecosystems that keep these sectors growing.

So, let’s make it easy for companies to choose regions like the North East. We can do that by developing affordable, high-quality manufacturing space designed to grow and flex with the needs of businesses.

Local authorities can stimulate this activity via grant support and local plans. And there are rewards for the public purse in the shape of business rates returns and high-value job creation.

We will also need sophisticated data and business cases to help convince companies of the benefits of reshoring. Covid-19 has changed the attitude of many firms towards supply-chain risk. When the virus began to affect Chinese production earlier this year, we started to see problems.

While China and South East Asia are ramping back up again, there’s an opportunity to promote the North East as a second location – a place to site even a small percentage of production to mitigate against future crises.

Let’s be realistic though: many firms will find the costs of reshoring too high. This is where sense of scale is also important. There is a growing need for manufacturing flexibility and adaptability at a smaller scale. Consumer markets are evolving fast and many products have much shorter life-cycles, meaning agile production is really important.

Few products are completely manufactured in one place. Manufacturing in the UK tends to take component parts and use precision processes to turn them into another part that is then exported for use in the end product. Covid-19 has upset that chain.

Reshoring is a key part of the solution to help regions like the North East get back on track and future-proof against the possibility of further disruption. From environmental benefits to attracting inward investment, the UK property sector should be evangelical about the positives of reshoring.

Our focus now should be on providing the high-quality, flexible and cost-efficient space businesses need to come home and get the British economy thriving again.

Keith Taylor is managing director of UK Land Estates

No comments yet