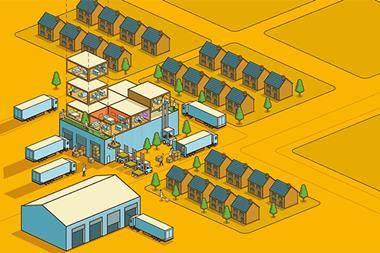

Offsite manufacturing has been at the forefront of the housing agenda over the past year.

Major deals have made a big media splash and increasing political support from a conveyor belt of housing ministers has proved that this is more than just a flash in the pan.

What’s most exciting is that this step change in delivery is ushering forth a new band of investors and highly skilled innovators to disrupt an industry that has barely evolved for decades. Coming from a major housebuilder, I know first hand that the industry could be working far more collaboratively and recent activity around offsite manufacturing is really positive.

And we’ve begun to see this happen. In April, Goldman Sachs invested £75m in modular housing newcomer TopHat. Shortly after, Japan’s largest housebuilder, Sekisui House, set its sights on the UK modular market, pumping £90m into Urban Splash, with the support of Homes England.

Meanwhile, in May, we announced the UK’s largest-ever modular housing deal with Places for People. The strategic partnership will see the delivery of 750 high-quality sustainable and affordable homes to sites up and down the country. We’ve already delivered more than 300 homes to locations across the UK in just our second year of operation.

Next year, we’ll have a pipeline of more than 1,500 homes, delivering a range of opportunities, including land-led schemes (secured by our land team), turnkey packages (inclusive of groundworks) and individual manufactured units, white-badged such that they can be customisable to work across a variety of tenures and to a range of clients.

The growing interest from some of the world’s biggest investors and housing leaders is simple: the industry needs shaking up, and fast. The housing crisis poses considerable challenges, but more pertinently, it presents an enormous opportunity.

Following the announcement of our strategic partnership, National Housing Federation boss Kate Henderson said: “This is the single biggest modular housing deal yet, and the fact that it has been led by a housing association speaks volumes about where we as a sector are at.”

Institutions, real estate investment trusts, banks, housing associations and foreign housing developers have all invested: this level of industry confidence all but dismisses the claims that modular is merely a fad. But perhaps what is most striking about these deals is what they all have in common: public support.

Public-private partnerships (PPPs) are quickly becoming the favoured approach to tackling the housing crisis. They open up new revenue streams for local authorities and public bodies, generating cashflow while more equitably distributing the risk.

A more joined-up approach to delivering homes brings a range of benefits. By combining the capabilities of local authorities and private companies, partnerships can result in faster project completion and reduced delays. In addition, a strategic partnership’s return on investment might be greater than projects with traditional, all-private or all-governmental fulfilments. This is because innovative design and delivery methods, such as modular, and financing approaches become available when two entities work hand in hand.

Public and private partnerships can act as the perfect trade-off. Local authorities know and understand the community far better than private developers. Meanwhile, the private sector can wield its expertise and financial weight, invigorating the competition and driving innovation within the market. Pioneering sectors such as offsite manufacturing and dynamic tenure types such as build-to-rent have flourished in recent years as a result of the private sector’s determination to innovate. And this is to the benefit of everyone.

Offsite manufacturing means we can precision-engineer exceptional homes that are considerably more energy efficient than the average traditionally constructed new-build, can be delivered to a site twice as fast and can produce up to 90% less onsite waste, and we are the first volumetric housing manufacturer with a range of house types all backed by the coveted NHBC system accreditation.

The variety of tenures in terms of exit routes for some of the nation’s housebuilders and contractors grows apace with build-to-rent, the private rented sector, discount market rent, affordable rent, social rent, rent to buy, shared ownership and starter homes, which in turn has seen some of the country’s largest institutions and investors flood the market. The thing that all these investors are looking for is secure low-risk investments (as much of the capital is coming from our pensions) but let’s not pretend that underpinning this is a desire to maximise returns.

Offsite manufacture is the perfect foil. With delivery at more than twice the speed of traditional housing, investors will be able to recognise returns much earlier, driving core metrics in terms of return on capital employed and internal rates of return. Perhaps more importantly, this is bringing forward much-needed homes to those most in need.

This is where PPPs are so effective: in delivering high-quality, affordable homes. And no sector has the potential to do that than modular.

This, in particular, is what attracted me most to the sector and led to my recent decision to join ilke Homes. Offsite manufacturing provides a huge opportunity to drive genuine and durable change, and through my experience in the wider housebuilding industry, I hope to play some part in that.

We are only at the beginning of our journey. Moving forward, we want to engage with as many partners as possible because ending the housing crisis is now a joint mission.

The only way is up for modular. And the deals that have materialised over the last six months prove that modular is here to stay. But for the growth to continue, PPPs must be at the forefront of change through collaboratively delivering exceptional homes at scale.

If we are serious about achieving the government’s lofty 300,000-homes-a-year ambition, then we need to bring everyone to the table, with a joint purpose, and that’s exactly what I plan to do.

Matthew Bench is group executive director of growth and partnerships at ilke Homes

No comments yet